Thursday was the ribbon cutting for the Lucile Packard Children’s Hospital at Stanford.

The event was small, and our friends at HGA gave us one of their tickets, so I was able to attend. And, I’m so glad I did. Thank you HGA!

The event was mostly for the donors who had helped to create the funding for the project. Speakers included all manner of dignitaries, each talking about this hospital being the most technologically advanced, patient-centered, and environmentally sustainable children’s hospital in the world.

I can be pretty emotional, and I was really moved when I listened to a mom tell the story of her daughter, diagnosed at age two with leukemia, and their fight, with the people at Packard Children’s, to save her life. I confess I was one of those who wept, then, when another young woman took the stage to sing. This woman had been diagnosed with Stage 3 ovarian cancer, and had, during her therapy at Packard Children’s, entered America’s Got Talent. Apparently, her singing went viral, and she gave us her song, “This is my fight song”, and she brought up the little girl who had been saved from leukemia. It was a powerful moment (to say the least).

We (Mazzetti with several design partners) started working on this project more than a decade ago. I remember all of the people who have come and gone from the project. I celebrate, especially, the genius of my friend Robin Guenther, of Perkins + Will, who lead the team to create this masterpiece of healing. As we were working on the project, Robin and I also collaborated to win the Kaiser Small Hospital Big Idea competition, and, though Kaiser never built the building we envisioned, pieces of it made their way into this building. I feel so fortunate to have been able to work with Robin through these years and to do this project with her.

Shortly after the ceremony, back at our San Francisco office, I talked with my Mazzetti colleagues about the project. As I looked into their eyes, I saw so many people who did so much work on the project. I told them that truly, they were the ones who should have been there, for they were the ones who made this building happen. I told them about the two kids who had appeared, and how it reminded me that our work makes a difference.

A long time ago, I reconciled myself to the fact that my talents were not ones that would allow me to practice medicine. But, through the years, I have consoled myself that, at least, I can help to create the stage on which those with these talents can do the work of taking care of people who need help.

Doing what we can to create the most patient-centered, technologically advanced, environmentally sustainable medical centers in the world, so that medical professionals can treat, and so that people can heal—this is my fight song.

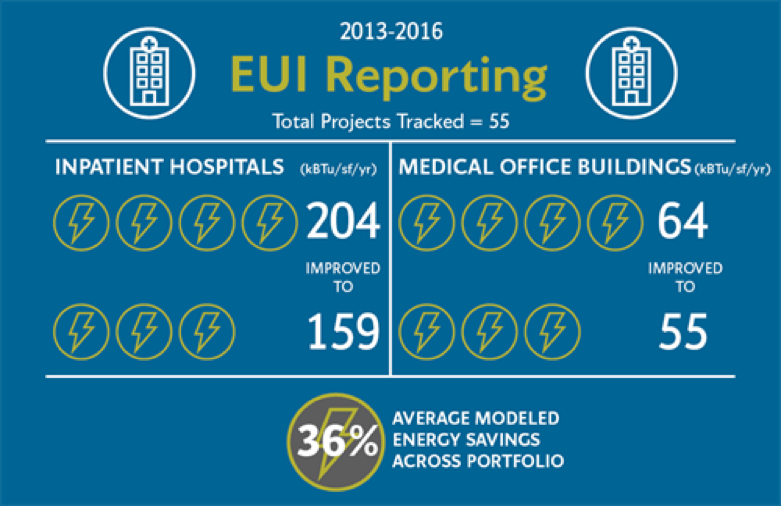

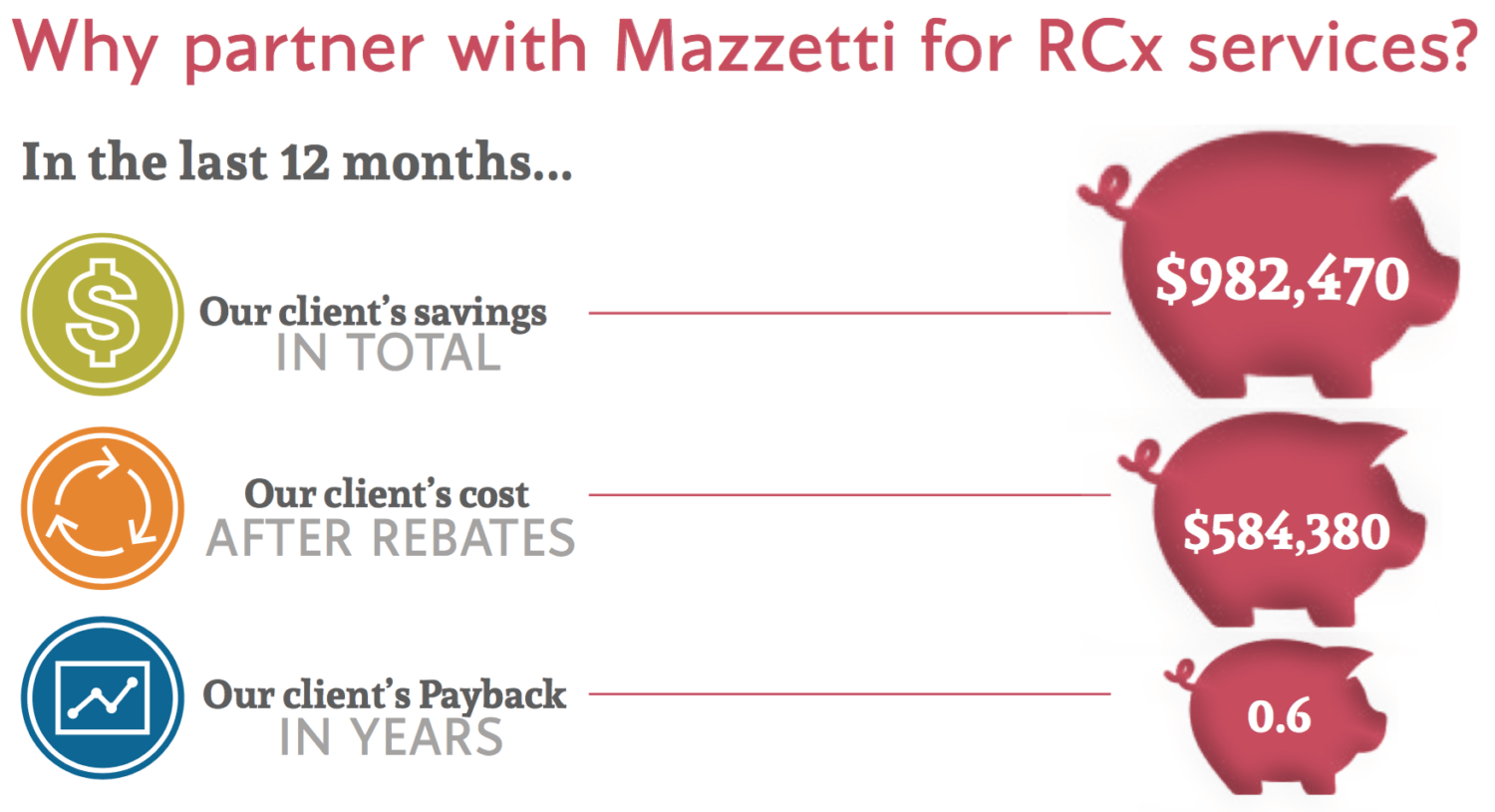

And, most importantly, we deliver. If modeling is step 1, measuring is step 2. We’re excited to let our projects speak for themselves. In upcoming “Energy Peace of Mind” chapters, we’ll be featuring various projects for which we have modeled and measured energy data. This is about outcomes, not activity.

And, most importantly, we deliver. If modeling is step 1, measuring is step 2. We’re excited to let our projects speak for themselves. In upcoming “Energy Peace of Mind” chapters, we’ll be featuring various projects for which we have modeled and measured energy data. This is about outcomes, not activity.

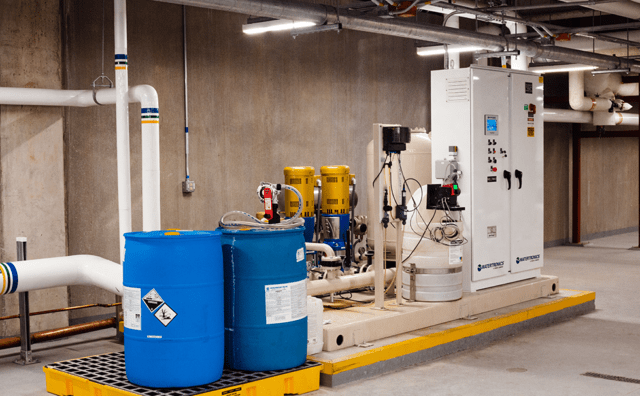

Indeed, the energy design of this building was so critical, that in early stages of the project, we worked with the EIR team to craft a Carbon Emissions forecast and a set of sustainability strategies from water to effluent to energy that are remarkable in their aspiration. Many of these ideas originated from the

Indeed, the energy design of this building was so critical, that in early stages of the project, we worked with the EIR team to craft a Carbon Emissions forecast and a set of sustainability strategies from water to effluent to energy that are remarkable in their aspiration. Many of these ideas originated from the