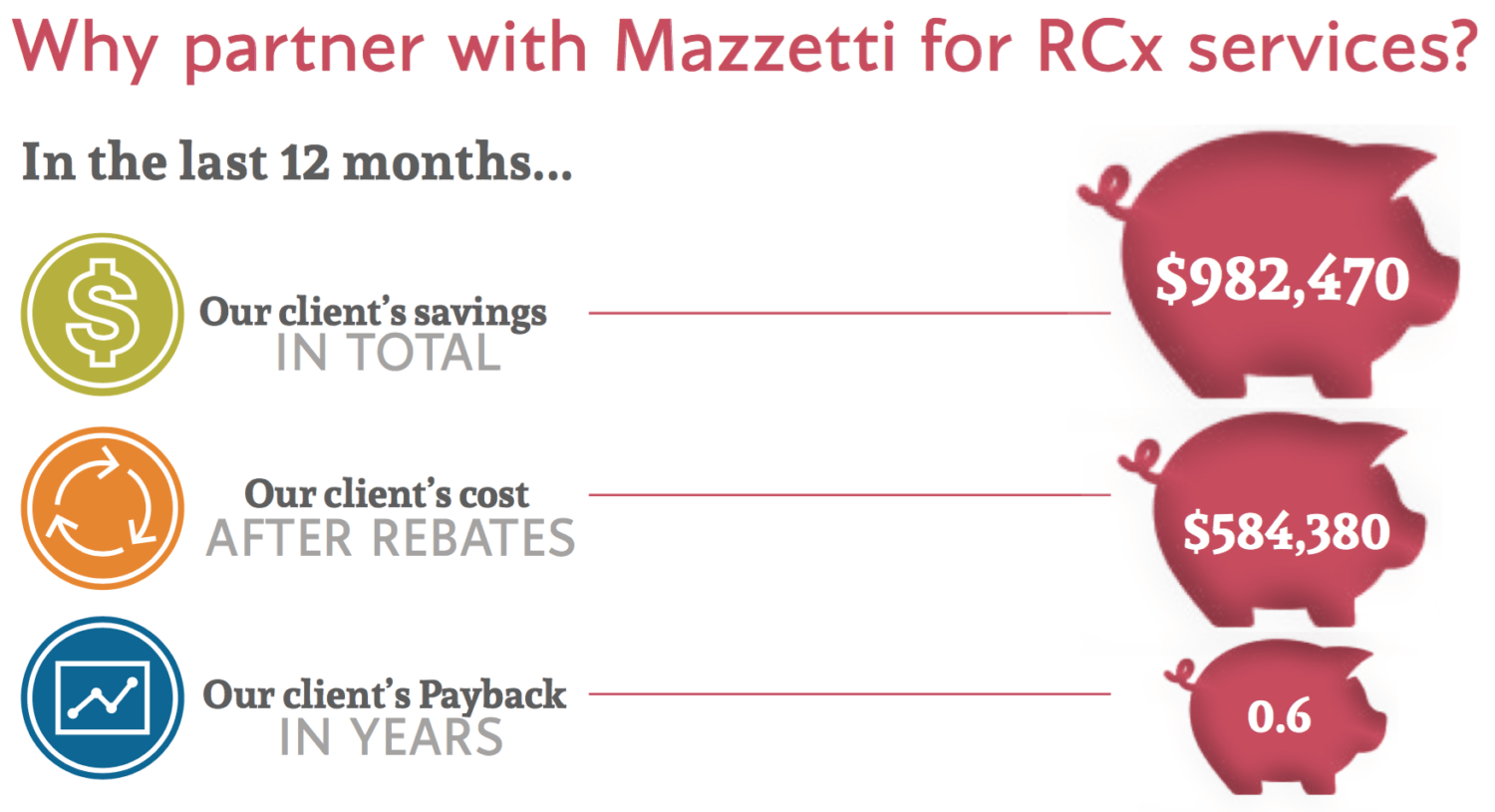

Over the last 12 months, one of our valued clients has saved a total of $983,470 from RetroCommissioning (RCx) services. Their cost after rebates was $584,380, with a payback of 0.6 years! Thanks to the assistance of Mazzetti’s experts, our client has reaped the benefits RCx services can provide. See more details here.

Are you reaping these benefits?

As industry experts, our responsibility is to see opportunities for our clients and advise accordingly, especially opportunities for savings and energy reduction. According to the 2017 Johnson Controls Energy Efficiency Indicator (EEI) Survey , HVAC equipment remains the most popular improvement. These mechanical systems often operate inefficiently for various reasons–lack of funding for repairs or replacement, insufficient knowledge of proper operation, inadequate staff, and poor documentation, to mention a few. Temporary repairs are common, and in the age of sophisticated systems, small issues can often manifest into large problems in healthcare facilities. Through the RCx process, building owners are made aware of specific areas requiring attention and restore their building’s performance with the help of a detective.

What exactly is RCx?

RCx is a systematic process for identifying and implementing operational and maintenance improvements in a building to ensure continued healthy performance over time. RCx goes beyond maintenance measures to identify deficiencies that aren’t always so obvious. That experienced detective, also known as a Commissioning Authority (CA), provides strategies that can lower utility bills and provide other benefits–reduced maintenance costs and improved occupant comfort and indoor air quality.

Low-hanging fruit

Consider your own facility. How confident are you in the effectiveness of your existing Building Automation Systems (BAS)? Do you think you’re “ringing out” (hence the banner image) the full value of your BAS to increase efficiencies, particularly re energy efficiencies? The data suggests more value is available for most facilities with little to no capital costs.

You can discover more about Mazzetti’s Cx and RCx solutions (including our EXPERTS) here.

Did you know, that if your facility runs at a 5% profit margin, every dollar in energy cost you save is equal to grossing $20 of additional revenue?

Our client recently distributed their annual savings report, which documents each project’s overall cost and savings. We thought this graphic might help illustrate, literally, reaping the benefits of RCX, “ringing out'” every ounce of value.

Interested to discuss possibilities for your facility, contact me..